Why and how

The surface of polymer materials is often not suitable for e.g. printing or adhesive joining. The surface free energy is low and the materials are inert. Therefore, surface treatments are applied to activate the surfaces on large industrial scale.

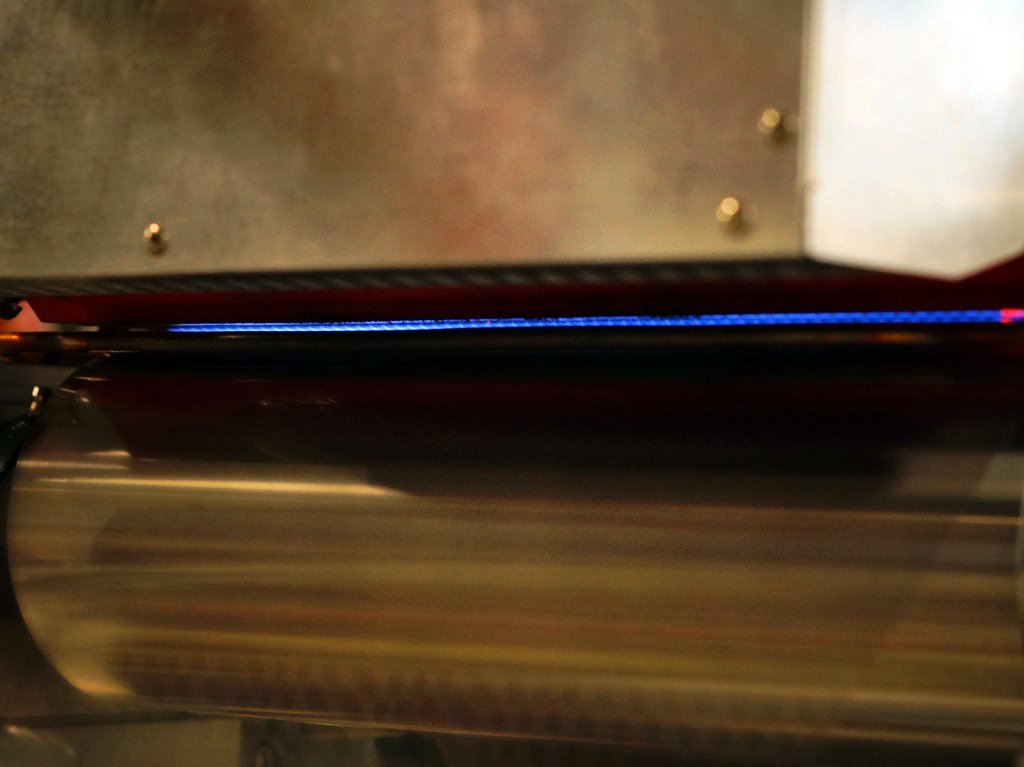

In an activation process the surface is oxidized in order to form polar functional groups which increase the surface energy and which can interact with other substances, be in water, paint or an adhesive. Electrical discharges and flames are often used to produce highly reactive species such as radicals, ions, or energetic radiation which initiate chemical reactions in the surface of polymer materials resulting in an oxidized surface. These processes are very efficient. Treatment times of milliseconds suffice.

The very efficient treatment results in a wider variety of chemical functional groups. In cases a more defined surface chemistry is required e.g. for a high performance adhesive joint or a carrier for biochemical diagnostics device. A combination of an activation and a classical chemical reaction can be a viable solution.

What we can do

We have equipment to treat surfaces ranging from laboratory scale to pilot scale. With this equipment and with sophisticated surface analytical tools we develop technologies for industrial scale surface treatments, support companies improving their products and production, and help if something does not work as suposed to.