Our services

- consulting

- feasibility studies

- technology development

- scale up

- process monitoring and control

- equipment selection

- quality assurance

- personnel training

Our technologies

- activation and functionalization with low pressure plasma

- plasma-enhanced thin film deposition

- photochemical functionalization, in particular with vacuum-ultraviolet excimer radiation

- advanced flame treatment

- functionalization of polymer surfaces using gas phase and liquid phase chemical reactions

- printing chemistry

- surface analysis

Our equipment

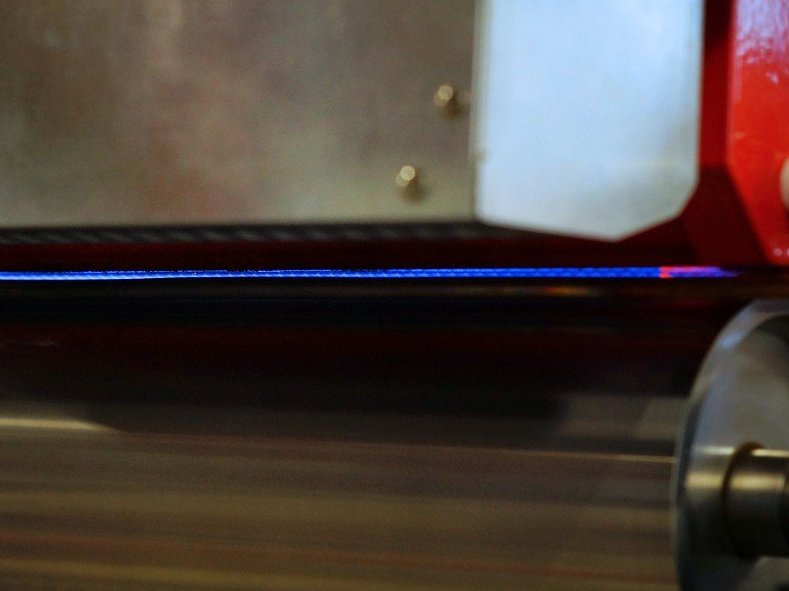

Our equipment ranges from laboratory scale up to small industrial scale. We can do plasma treatments in a chamber with up to 0.4 m3. Webs (films, fabrics) can be treated at a width of up to 30 cm with low pressure plasma as well as with Corona (dielectric barrier discharge), flames, VUV lamps, with various printing techniques at atmospheric pressure.

For the analysis of surfaces and thin films we use state-of-the-art instrumentation.

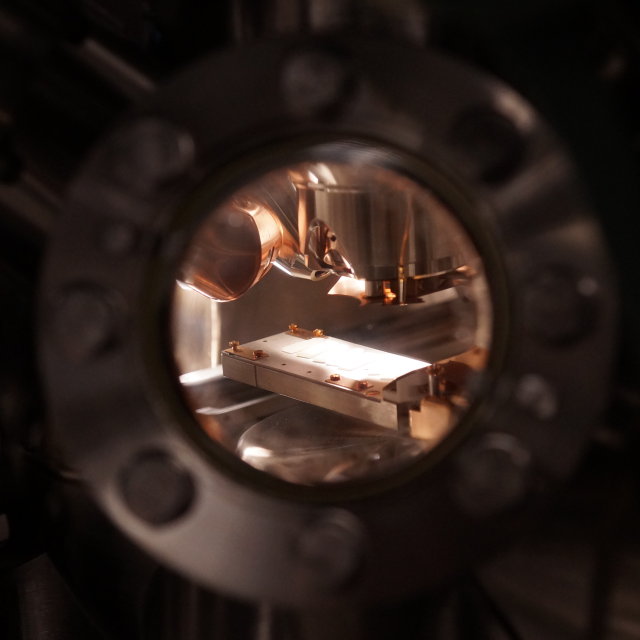

New XPS instrument

Just recently we have installed our brand new XPS machine. With this Kratos Axis Supra+ we enter a new era of surface analysis in our institute.

Of course, we offer surface analysis as a service. Our customers benefit not only from the high end analytical equipment but also from our expertise in polymers.

Fraunhofer POLO

Together with Fraunhofer colleagues we joined our competencies and equipment in the area of polymer surfaces. We can support our clients in complex projects, too. Fraunhofer POLOcan realize complex projects for clients developing new concepts, innovative processes, and modern materials based on the surfaces of plastics and natural polymers.

Plasma Germany

We share our experience with companies, universities and research institutes in Germany and contribute to disseminating knowledge about surface technology by participating actively in Plasma Germany (German). In particular, in the field of plasma and polymers we contribute to the exchange of experiences.

R2R-Net

Continuous roll-to-roll (R2R) processes are an important path for scaling up surface functionalization of flat substrates. We joined our activities in this field with others when we founded R2R-Net.

R2R-Net is an effort intended to connect companies and institutions working in the field of R2R surface functionalization. For more details and for joining please see here.