Surface functionalized polymer powders can be used in various applications ranging from functional sintered materials to sample preparation in microbiology.

Functionalization of polymer powders

Activation

pulsed plasma treatment of polymer powder in a fluidized bed reactor

The surface functionalization always starts with the activation. Oxygen containing low-pressure and medium-pressure plasmas are versatile tools. In the simplest case a sheet of the powder can be oxidized in a low pressure plasma. The penetration ability of oxygen atoms allows treating layers of several millimeter thickness depending on the structure of the powder particles.

In a fluidized bed system the activation with an air plasma works well for batch sizes of some 10 g. The video shows a plasma activation treatment with pressure pulses.

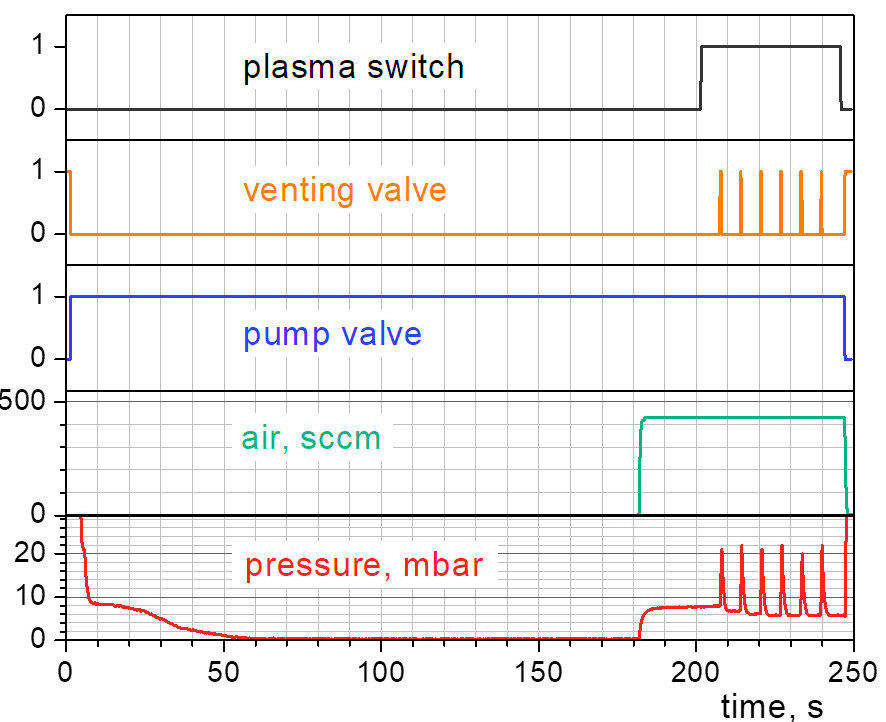

The process for the plasma treatment of the polyethylen powder is programm controlled. A computer software starts the pumping, the gas flow, the plasma etc. For a more homogeneous treatment of the powder the venting valve is opened for fractions of a second several times during the treatment. Various parameters are recorded during the treatment for the purpose of documentation of the process parameters. The figure shows an example of such parameter traces.

Larger amounts of powders can be activated in a rotating drum low-pressure plasma system.

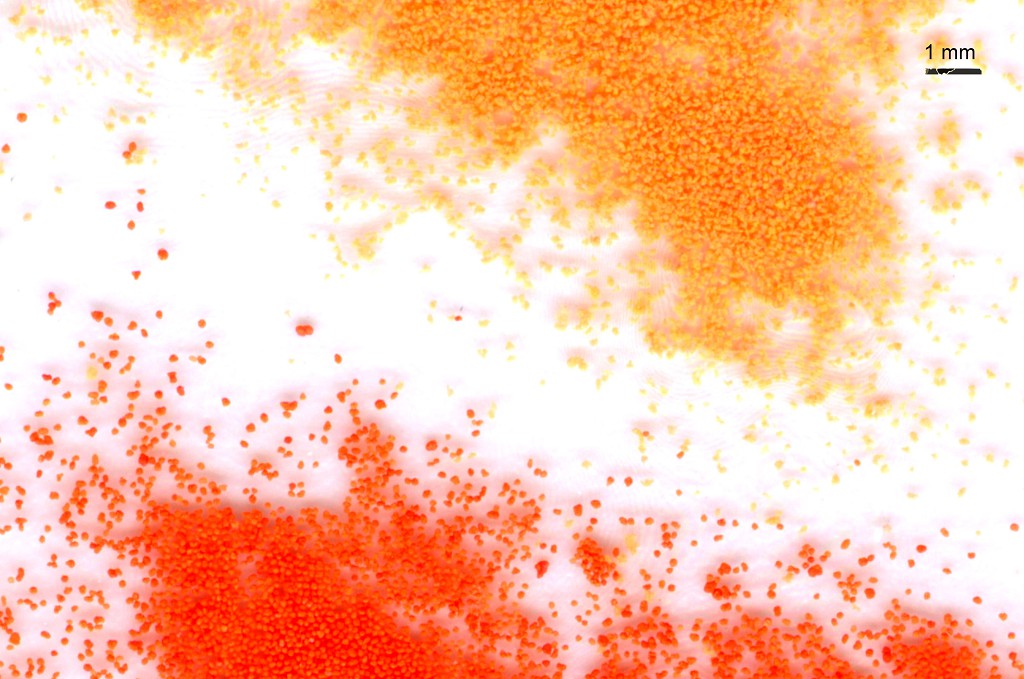

Different levels of surface activation of polyethylene powders dispersed in water.

The success of the activation can be tested by dispersing the powder in water. The hydrophobic polyethylene floats up immediately. The particles of a well activated hydrophilic powder remain dispersed for some time.

Functionalization

It was found that surface functionalized polyethylene powder can be used for the sample preparation in microbial diagnostics. For example, this powder is dispersed in a large volume of a beverage and captures bacteria. Then the powder is removed by a simple filtration. The relatively small amount of powder is compatible with the volume of analytes which are used in microbiological diagnostics. In this way 100 bacterial cells per liter beer can be detected. In a similar procedure the microbes can by insulated from e.g. soils samples.

The powder is functionalized in a two-step process including a plasma activation and the coupling of a functional polymer (poly(ethylene imine)) in a second wet chemical step. The functionalization can be visualized by dye staining.

The complete process was scaled-up and transferred to the company GEN-IAL GmbH in Troisdorf (Germany) which sells these surface functionalized powders to the quality control departments of the beverage industry.