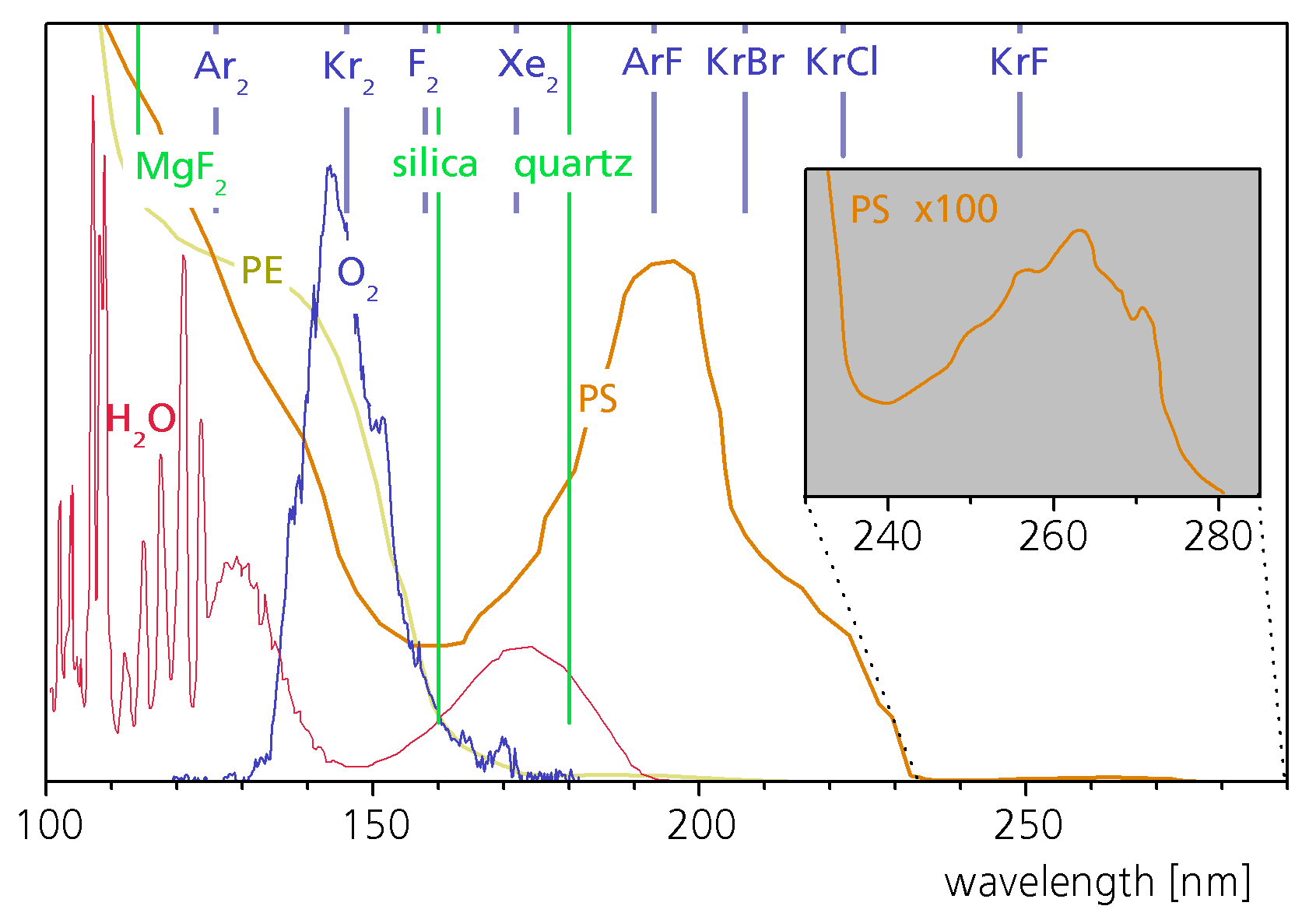

VUV absorption

Gases like oxygen, carbon dioxide, and water vapor absorb in the VUV region. The absorption is dissociative, i.e. it results in the formation highly reactive fragments like oxygen atoms or hydroxyl radicals. Other gases like nitrogen do not absorb. For technical applications of VUV excimer radiation it might be necessary to reduce the partial pressure of oxygen by the addition of nitrogen in order to adjust the amount of light absorbed by the gas and the amount absorbed by the substrate surface. Depending in this ratio, a process can work in different modes:

- the polymer is excited and reacts with the gas

- the gas is excited and reacts with the polymer

- gas and polymer are excited both

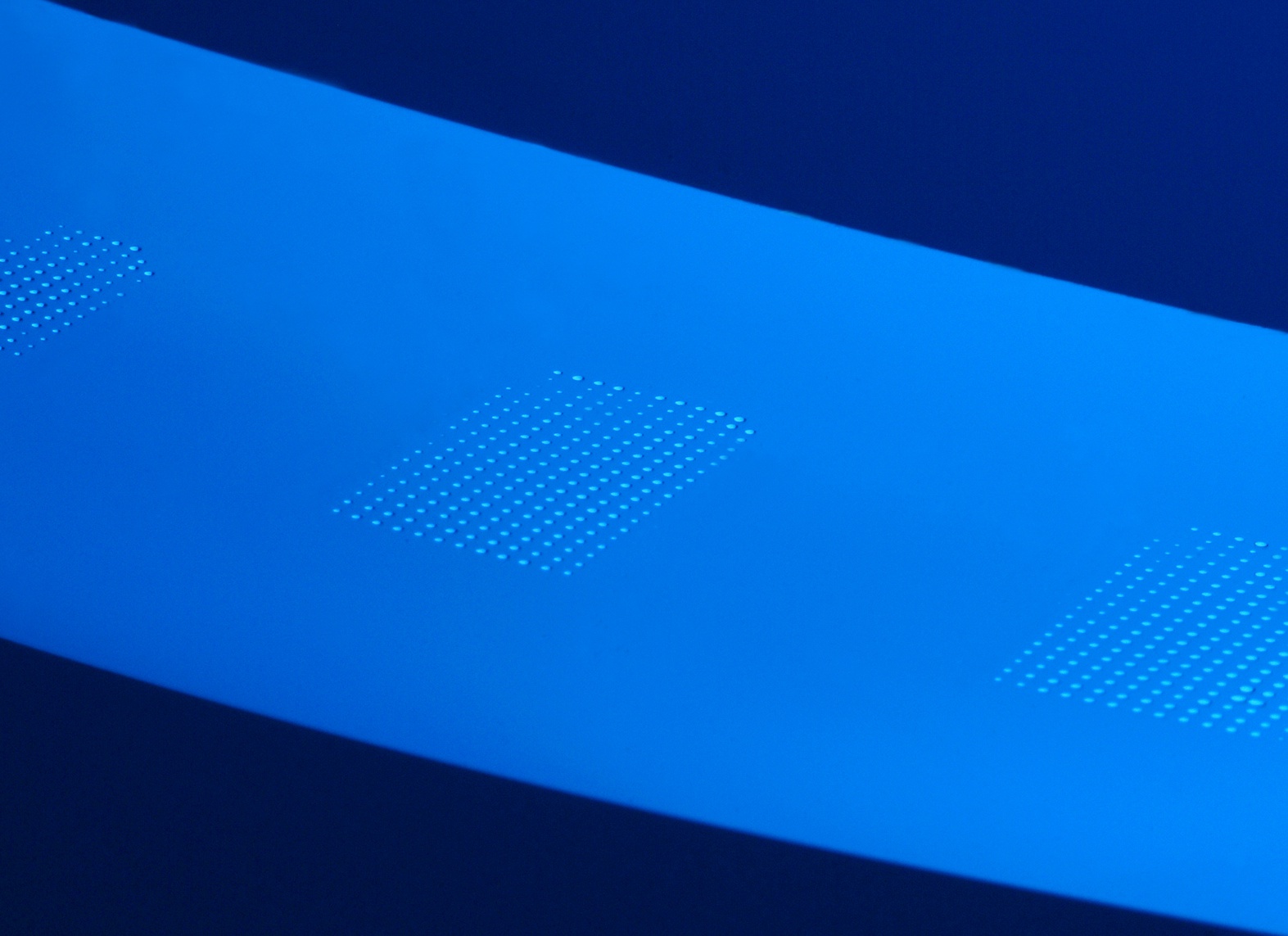

VUV-excimer radiation can be used for the activation of polymer surfaces and for the removal of contaminants, in particular in applications where traditional treatments with corona discharges or barrier discharges are not applicable. It is an optical technique and, therefore, the substrate is not subjected to electric fields. For example, metallized plastics can be treated without damaging the metal. When using masks it is straight forward to make a structured activation which is difficult to do with discharge plasmas.

Structured treatment

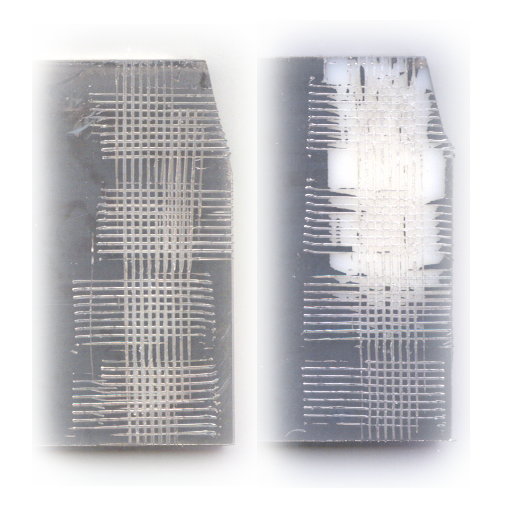

With our programmable roll-to-roll treatment system we are able to move a film stepwise and do an irradiation of the film while it stands still. In the case of an hydrophobic COC (cyclic olefin copolymer) film the irradiation results in a surface oxidation at the exposed areas which than become hydrophilic.

This structured activation can be the first step in a series of functionalization reactions. It provides functional groups which can be used for following reactions with gaseous or liquid agents immediately after the excimer treatment. At the end this functionalized surface is suitable for a metallization or for a microarray (biochip) which holds a set DNA fragments or proteins.